VDA 6.3 Potential Analysis Audits

VDA 6.3 Potential Analysis Audits to Qualify and Assess New Suppliers Globally

Pro QC International has developed wide-reaching expertise over 40 years of providing quality solutions in the automotive industry. We support OEMs and suppliers by auditing their suppliers against VDA 6.3 with Potential Analysis audits conducted on-site by experienced auditors with an automotive background.

As a global quality assurance company, Pro QC offers VDA 6.3 Potential Analysis audit services in the main automotive manufacturing regions of Europe, Asia, North America, the Middle East, and Africa.

Pro QC also deploys the VDA 6.3 Potential Analysis framework to assist our non-automotive clients to evaluate their suppliers.

Contact Us

Whether you work for the automotive industry or not, the VDA 6.3 potential analysis audit is an excellent framework for assessing the reliability of your potential suppliers.

What is VDA 6.3 Potential Analysis Audit?

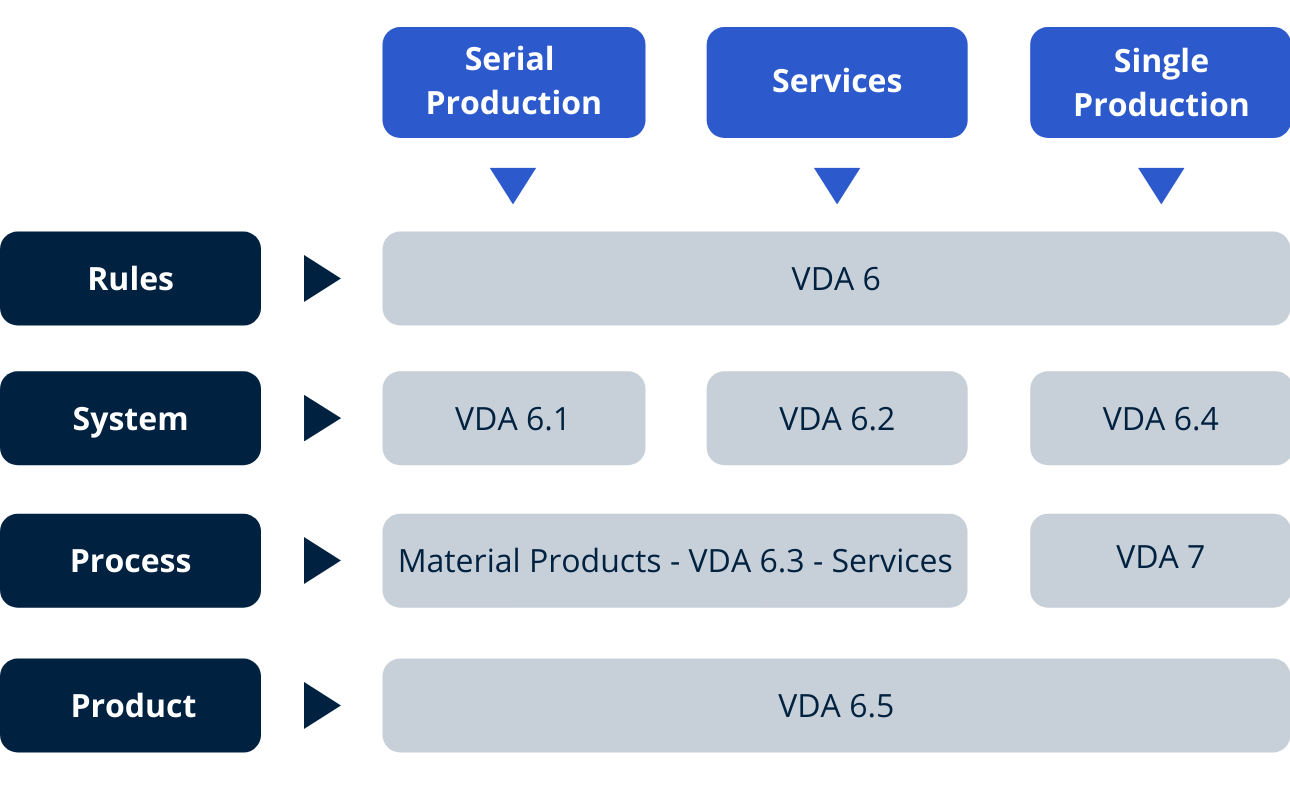

VDA 6.3 is a standard used by German automotive companies and is followed by companies that supply to German car manufacturers such as Daimler, Volkswagen, and BMW. It is an auditable standard comprised of 7 parts (P1, P2, P3, P4, P5, P6, P7).

The first phase of any manufacturing project is a supplier qualification. The VDA 6.3 standard labels this phase P1 – Potential Analysis. The purpose of the VDA 6.3 Potential Analysis is to evaluate potential supplier’s quality system and their ability to systematically deliver product and service quality for the client’s specific product line.

For existing suppliers, the potential analysis is also used to evaluate new factory locations, new production lines, or the introduction of new technologies for new products.

What is the difference between VDA Potential Analysis and VDA 6.3 Process Audit?

The VDA 6.3 Potential Analysis audit covers P2 to P7 on a system level for your potential suppliers. The VDA 6.3 Process Audit also covers P2 to P7 as well as P6.1 to P6.6 using a process audit approach for existing suppliers. The VDA 6.3 Process Audit is more extensive than the VDA 6.3 Potential Analysis audit and you can learn more about it here.

VDA 6.3 Potential Analysis Audit Approach and Checklist

Pro QC’s audit team follows a proven method to audit against the VDA 6.3 standard. Our auditors will walk the production line, identify potential risks and gather objective evidence according to the VDA 6.3 framework described below:

- General information on the supplier

- P2 – Project Management

- P3 – Planning the product and process development

- P4 – Implementation of the product and process development

- P5 – Supplier management

- P6 – Process Analysis/Production

- P7 – Customer care/customer satisfaction/service

Next, our auditors will provide a report summarizing all the potential risks and actionable findings, and finally determine the supplier’s risk level based on the objective evidence that was gathered on site.

Pro QC’s VDA 6.3 Potential Analysis audit services are impartial due to our independent relationship with the auditee and our methodical approach. Our report will also be reviewed by our supplier quality manager prior to submitting it to our client.

Pro QC’s VDA 6.3 Potential Analysis Audit Outcomes

Report delivered within 72 hours of audit

The audit report highlights the strengths and weaknesses of the supplier. The report will provide the client with the crucial information needed to make informed decisions on business relationship viability and a course forward with the supplier.

The VDA 6.3 Potential Analysis result helps prepare for a nomination decision and sorts the supplier into one of the following categories:

- Barred supplier: Nomination is not possible

- Controlled supplier: Nomination is potentially possible, but requires corrective actions

- Approved Supplier: Nomination is possible

Complete audit reports are usually delivered within 72 hours after the service and include:

- A summary of the audit

- The overall audit results

- The compliance level for each part of the standard (P2, P3, P4, P5, P6, P7)

- A list of recommended corrective actions

- Objective evidence such as photos, interviews, and examined records and documents

Supplier management solutions

Pro QC supports a client to improve factory performance with supplier management solutions. After Pro QC audits the supplier against VDA 6.3 Potential Analysis and identifies nonconformances, the client may follow a clear path forward in establishing and implementing corrective actions and verifying them through comprehensive follow-up activities.

How is IATF 16949 different from VDA6.3?

IATF 16949 is a quality system audit, which is verified and conducted by a third party or second-party auditor (like Pro QC). VDA 6.3 is a process audit, which is usually conducted by your company’s customers (first-party audit) or qualified auditors (second-party audit) according to the VDA 6.3 framework.

It is also worth noting that there is VDA 6.3 third-party certificate, but rather a positive audit result is one piece of objective evidence to demonstrate your competency to your automotive client.

Pro QC International has a quality assurance team supporting the automotive industry in all major manufacturing countries.

Pro QC International

Our Service Reports

Detailed & Actionable

- Following International & Industry Standards

24 Hours

- Report Delivery forInspections

48-72 Hours

- Report Delivery for Audits

Download Sample Reports

Pro QC Blog Posts & Related Offerings

Find out more about our related services by clicking below:

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 227 189 7407

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.