A Quality Management System (QMS) audit is a critical evaluation process that helps organizations maintain and enhance their quality standards by ensuring adherence to documented policies, procedures, and processes.

A strong QMS provides the framework for operational and quality excellence, guiding organizations to deliver consistent products and services that meet or exceed customer expectations. Pro QC’s quality management system audits offer an in-depth assessment of supplier capabilities, ensuring they align with industry standards and regulations, thereby reducing risk and improving overall performance.

Contact Us

Our range of technical audits

Pro QC offers a range of technical audits that assess production capability and performance of your supplier against industry quality standards.

Assess your supplier’s production capability and performance.

Help them achieve operational and quality excellence.

What is a Quality Management System Audit?

A QMS is not just a tool for regulatory compliance; it is a comprehensive framework designed to foster a culture of quality and efficiency across all levels of an organization. From top management to the production floor, a QMS involves every stakeholder in achieving the organization’s quality objectives by documenting and streamlining policies, procedures, processes, and responsibilities.

During a QMS audit, auditors assess whether the organization’s QMS is effectively implemented and maintained, ensuring consistent product quality and compliance with relevant standards. Regular QMS audits help organizations identify gaps, improve processes, and maintain industry competitiveness. The most recognized QMS standard is ISO 9001:2015, which serves as the foundation for various industry-specific standards, such as IATF 16949 for the automotive industry and ISO 13485 for medical devices.

Pro QC’s Comprehensive QMS Audit Services

Pro QC offers a wide range of QMS audits tailored to meet the specific needs of different industries. Our audits assess the supplier’s quality management system by reviewing their policies, procedures, and critical documentation. It assesses the implementation of procedures on the shop floor along with the associated documentation. Below is an overview of our primary QMS audit services:

ISO 9001:2015 Quality Management System Audit

The ISO 9001:2015 is the most recognized and widely implemented QMS standard globally. It serves as the foundation for other industry-specific standards and applies to any organization, regardless of its size or sector. Our ISO 9001 quality management system audit ensures supplier processes are capable of consistently delivering quality products and services.

IATF 16949:2016 Quality Management System Audit

Specifically designed for the automotive industry, IATF 16949:2016 builds upon the ISO 9001 standard with additional requirements specific to automotive production and relevant service part organizations. Pro QC’s IATF 16949 audits help automotive suppliers meet stringent industry demands, ensuring that their QMS aligns with the highest quality standards.

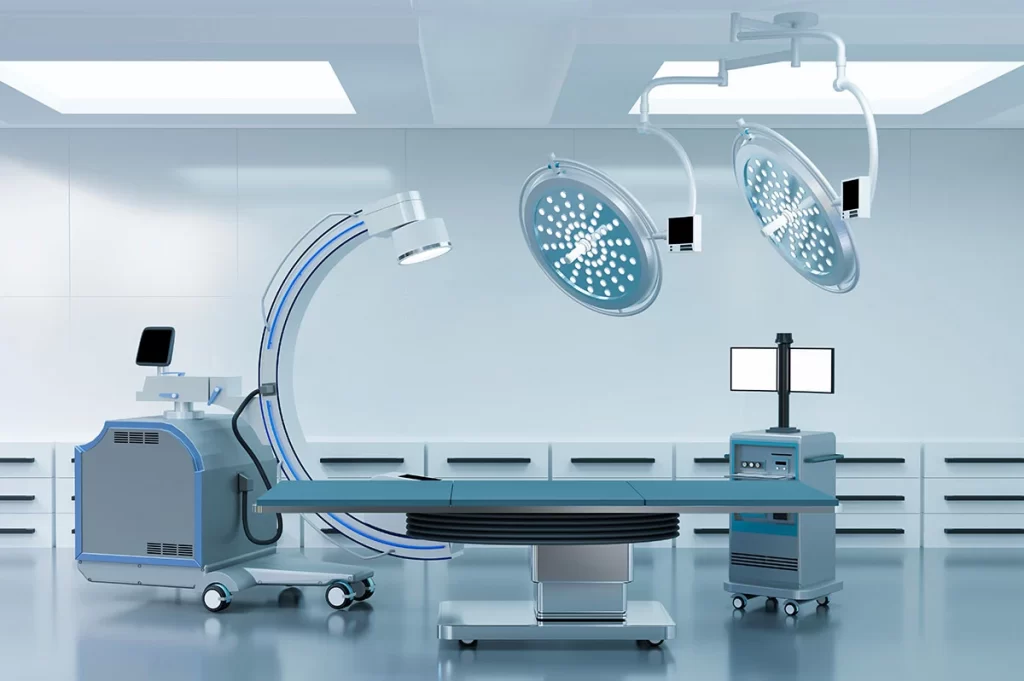

ISO 13485:2016 Quality Management System Audit

For the medical device industry, ISO 13485:2016 sets the requirements for a QMS that consistently meets customer and regulatory requirements. Our ISO 13485 audit assesses a supplier’s ability to produce safe and effective medical devices, ensuring compliance with international standards.

AS9100 Quality Management System Audit

The AS9100 standard is specifically designed for the aerospace industry. It incorporates ISO 9001 while adding additional requirements relevant to aerospace manufacturing and defense organizations. Pro QC’s AS9100 audits help aerospace suppliers ensure that their QMS meets the rigorous demands of the industry, including product safety, risk management, and reliability.

VDA 6.3:2023 Potential Analysis & Process Audit

VDA 6.3 is a process-based auditing standard used primarily in the automotive industry. It evaluates and improves controls related to new product introduction and manufacturing processes. Pro QC’s VDA 6.3 audits focus on ensuring supplier processes are capable of delivering products that meet the required specifications consistently.

MDSAP (Medical Device Single Audit Program)

MDSAP allows medical device manufacturers to undergo a single audit that covers the regulatory requirements of multiple countries, including the US, Canada, Japan, Brazil, and Australia. Pro QC’s MDSAP audits help streamline compliance for medical device suppliers, reducing the burden of multiple audits and ensuring global market access.

Additional Quality Management System Audits

Beyond these core services, Pro QC also provides audits for other specialized QMS standards, including:

- 21 CFR Part 820 (QSR) Audits for Medical Devices: Ensures compliance with FDA regulations for medical device manufacturers.

- ISO 22716 GMP Audit for Cosmetic Products: Focuses on Good Manufacturing Practices in the cosmetics industry.

- ISO 11137 Sterilization Process Audit: Assesses the effectiveness of sterilization processes for medical devices, ensuring safety and compliance.

- ISO 22000 Audit: Focuses on food safety management systems, ensuring organizations effectively manage food safety hazards.

- 21 CFR Part 110 Audit: Evaluates compliance with FDA Good Manufacturing Practices for food products, ensuring safe and sanitary production.

- 21 CFR Part 111 Audit: Assesses adherence to regulations for dietary supplements, safeguarding consumer health.

- 21 CFR Parts 210 & 211 Audits: Ensure compliance with FDA regulations for drug manufacturing, focusing on current Good Manufacturing Practices (cGMP).

When to Use Pro QC’s QMS Audits

Quality Management System audits are essential at various stages of the supplier relationship:

- Qualification and Onboarding of New Suppliers: Before onboarding a new supplier, a quality management system audit can verify their ability to meet the strictest quality standards.

- Ongoing Supplier Evaluation: Regular audits help maintain supplier performance and address any issues that arise over time.

- Post-Corrective Actions: After a quality issue has been identified, a QMS audit ensures that corrective actions have been effectively implemented.

- Preparation for Certification: For suppliers seeking to achieve or renew certifications, a QMS audit can help identify areas for improvement before the official certification audit.

Our QMS Auditor Team and Global Coverage

Pro QC’s team of QMS auditors is comprised of industry experts with years of experience conducting quality management system audits across various sectors. Our auditors are certified and undergo rigorous training to stay updated on the latest standards and best practices, ensuring that they deliver accurate and reliable audit results. With our globally aligned operation and network of specialists in Asia, Europe, the Middle East, Africa, and the Americas, we conduct QMS audits wherever our clients’ suppliers are located, providing consistent and reliable service worldwide.

Pro QC’s Quality Management System Audit Process

Our approach to Quality Management System (QMS) audits is designed for efficiency and effectiveness, as outlined below:

- Initial QMS Audit Assessment: Conduct a comprehensive evaluation to identify strengths and areas for improvement.

- Corrective Action Plan: Develop a tailored plan to address any non-conformities or gaps discovered during the audit.

- Implementation Verification: Ensure corrective actions are effectively implemented through thorough follow-up activities.

- Ongoing Monitoring: Schedule annual follow-up visits, adjusted according to supplier risk levels, to maintain continuous improvement.

- Performance Tracking: Provide a detailed supplier portfolio dashboard and performance analysis to monitor progress and outcomes.

Our supplier management team can customize checklists to meet the specific requirements of our clients. By partnering with us, companies can reduce overhead, streamline quality management, and ensure all necessary actions are efficiently executed.

Supplier Quality Audits and Supplier Verification

Not all suppliers may have a certified QMS like ISO 9001. For such cases, Pro QC offers customized Supplier Quality Audits (SQA) and Supplier Verification Audits to assess the supplier’s ability to meet quality requirements. These audits are a cost-effective solution for verifying supplier legitimacy and making informed purchasing decisions.

Other Factory Compliance Solutions

Factories have a range of local and global best practices and compliance standards to consider when aiming to be a reliable manufacturing partner. If a particular standard is not listed here, visit our Factory and Supplier Audits page to explore our wide range of supplier management services. Our team has the relevant experience to provide a bespoke approach or solution to meet any validation or certification requirement.

The Benefits of Working with Pro QC for QMS Audits

Choosing Pro QC for QMS audits offers numerous advantages:

Stability and Expertise

Founded in 1984, over 40 years of experience make Pro QC a trustworthy and dependable quality partner.

Expert-Led Solutions

Technical expert advice from first contact ensures reliable solutions are executed with precision.

Qualified Resources

Resource transparency and the right qualifications safeguard your interests on every project at every supplier.

Single Contact Point

A single contact point for quality services globally simplifies your supply chain.

Stringent Technical Oversight

Meticulous technical preparation, guidance throughout the engagement, and report review by senior engineers.

Advanced Quality Analysis

Industry-leading quality dashboard, analytics, and supplier performance analysis tools and framework.

Global Aligned Operations

Operational processes are optimized and aligned for a seamless cross-regional experience.

Pro QC International

Our Service Reports

Detailed & Actionable

- Following International & Industry Standards

24 Hours

- Report Delivery forInspections

48-72 Hours

- Report Delivery for Audits

Pro QC Blog Posts & Related Offerings

Find out more about our related services by clicking below:

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 227 189 7407

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.