But first, what are the risks related to packaging non-compliance?

Non-compliant packaging can lead to additional costs, product launch delays or recalls, changes to documentation or packaging, as well as legal and financial obligations if a product’s packaging is deemed dangerous. Incorrect or missing labeling or packaging, lack of use of, or incorrect pictograms and signal words on the hazard label which excludes definitions of hazardous substances which may be restricted in the EU or US, could compromise safe use and put the health of citizens at risk if the products enter the market. If the packaging material contains excessive amounts of SVHCs (“substances of very high concern”), that in itself eliminates the product as legal for import or sale in the market. This can also result in heavy fines or forced recalls.What exactly are the packaging requirements for importing to the EU and US?

1) Importing to the EU

The European Union imposes REACH (Regulation, Evaluation, Authorization, and Restriction) regulations in addition to packaging regulations. This includes ensuring product packaging (inclusive of unit packaging and gift boxes), that are used for display and customer experience purposes, as well as protective packaging materials (including export master cartons), are compliant with both REACH and CLP (Classification, Labelling, and Packaging) regulations. REACH regulates substances including chemicals, heavy metals, and pollutants for all products placed on the EU market. It also applies to the material used in packaging, for example, cardboard and paper, PE and other plastics, metal cans, and plastic bottles. Additional regulations apply specifically to food and beverage packaging materials. For example, Directive 94/62/EC on Packaging and Packaging Waste regulates the chemicals and heavy metals present in packaging, noting that, in general, the sum of concentration levels of heavy metals present in packaging or packaging components shall not exceed 100 ppm by weight. There are two main regulations that you must comply with if you import, export, or manufacture food packaging materials in the EU:- Regulation (EC) No 1935/2004

- Regulation (EC) No 2023/2006

- Business operators (including importers) must provide a Declaration of Compliance (DoC)

- A traceability system must be established for FCMs from production to distribution

- Materials shall be labeled “for food contact” or any other symbol indication

Complying with EU Recycling Symbols

Recommended under directive 94/62/EC are recycling symbols for imports bound for the EU. Here are the key symbols you need to know for your packaging:-

The Green Dot

-

Mobius Loop

Packaging can be recycled

Packaging can be recycled

-

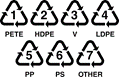

Plastic Resin Codes

Identifies the type of plastic resin used in the packaging

Identifies the type of plastic resin used in the packaging

-

Widely Recycled Label

The packaging can be recycled by 75% or more of local authorities across the UK

The packaging can be recycled by 75% or more of local authorities across the UK

-

FSC (The Forest Stewardship Council (FSC)) mark

Established to set standards on forest products, including wood and paper products such as furniture and product packaging

Established to set standards on forest products, including wood and paper products such as furniture and product packaging

Other important marks you need to know for EU-bound product packaging:

-

CE Mark

Indicates product compliance with EN standards or EC directives; the CE mark shall be affixed to the product unit, user instructions, and product packaging

Indicates product compliance with EN standards or EC directives; the CE mark shall be affixed to the product unit, user instructions, and product packaging

-

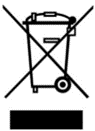

WEEE Mark

Indicates the end-user must send the product to separate collection facilities for recovery and recycling for end-of-life disposal; for all electrical and electronic equipment (EEE), the WEEE symbol must be printed visibly on the product

Indicates the end-user must send the product to separate collection facilities for recovery and recycling for end-of-life disposal; for all electrical and electronic equipment (EEE), the WEEE symbol must be printed visibly on the product

-

Food Contact Materials Symbol

The general principles of safety and inertness for all Food Contact Materials (FCMs) are stated in regulation EC No 1935/2004; this wine glass and fork symbol indicates that the material used in the product is considered safe for food contact. However, the regulation has been somewhat relaxed to exclude the need for the label for ‘obvious’ food contact products, including drinkware and cutlery

The general principles of safety and inertness for all Food Contact Materials (FCMs) are stated in regulation EC No 1935/2004; this wine glass and fork symbol indicates that the material used in the product is considered safe for food contact. However, the regulation has been somewhat relaxed to exclude the need for the label for ‘obvious’ food contact products, including drinkware and cutlery

2) Importing to the US

In the United States, the Fair Packaging and Labeling Act (FPLA) is enforced by the Federal Trade Commission (FTC) and enacted to facilitate value comparisons among similar products and prevent deceptive packaging and labeling claims of household goods.Labeling requirements

The FPLA sets a series of standards for product labeling contents in terms of wording, typesetting, design, units, and more. Here’s what you need to make sure is part of your labeling for packages bound for the US:- Identity of the commodity;

- Name and place of business of the manufacturer, packer, or distributor;

- The net quantity of contents, using the units of both the customary inch/pound system of measure;

- Labels should be in a distinctive style and contrast with other matters on the package;

- Labels should be printed in a font and typeface that are to be (i) in a fixed proportion to the main viewing window of the package, and (ii) consistent across all parcels of roughly equivalent size;

- Labels should consist of lines of text typeset that run horizontally when the container is in the orientation in which it is designed to be viewed

Poison Prevention Packaging Act (PPPA)

The Poison Prevention Packaging Act (PPPA) was enacted largely to protect children under the age of five from any unnecessary accidents linked to containers with potentially hazardous contents. This includes adequate labeling for products for household use, which may contain an excessive amount of chemicals and pollutants (generally medicines and cosmetic products). The PPPA also requires that all applicable product packaging be constructed in a way that makes it significantly difficult for children aged five and below to unpack.Uniform Packaging and Labeling Regulation (UPLR)

The Uniform Packaging and Labeling Regulation (UPLR) was designed to raise product safety awareness by demanding manufacturers and importers provide accurate and adequate information regarding their products, so purchasers can make price and quantity comparisons. The UPLR requires consumer packaging labels should bear the following:- Identity of the commodity (e.g., soap, hand soap)

- Name and place of business of the manufacturer, packer, or distributor

- Net quantity of contents or numerical count in metric units

California’s Rigid Plastic Packaging Container Law

In order to reduce the amount of plastic wastage and increase the recycling rate of used plastic matters, the state of California enforces the Rigid Plastic Packaging Container Law (RPPC). This law requires all products manufactured, imported to, and sold in California that uses rigid plastic packaging containers, must be compliant with one of the following requirements:- The container must be made from a minimum of 25% recycled materials

- The container must be reusable

- The container must be source-reduced (container weight reduced by 10%)

- The container must contain floral preservatives and later be used in the floral business

- The container must have a 45% recycling rate at the minimum

Country of Origin

19 Code of Federal Regulations (CFR) part 134 requires that every product imported to the US must bear a Country-of-Origin mark conspicuously and indelibly indicating the product’s source of origin.How does Pro QC control packaging compliance during a product inspection?

Our clients need to ensure their products are packed according to regulatory specifications and reach their customers in perfect condition. The packaging must also be durable enough to survive unpredictable weather, storage conditions, and rough handling during shipping.

We ensure a full check of the different materials used during the packing: bubble wrap, polystyrene sheets and chips, foam, cardboard box, bands (for strapping the cargo to the pallet), and pallets (for shipping larger and bulkier pieces of furniture).

Through a full quality control inspection for the packaging, we perform the below checks and test:

Our clients need to ensure their products are packed according to regulatory specifications and reach their customers in perfect condition. The packaging must also be durable enough to survive unpredictable weather, storage conditions, and rough handling during shipping.

We ensure a full check of the different materials used during the packing: bubble wrap, polystyrene sheets and chips, foam, cardboard box, bands (for strapping the cargo to the pallet), and pallets (for shipping larger and bulkier pieces of furniture).

Through a full quality control inspection for the packaging, we perform the below checks and test:

-

PACKING VISUAL CHECK

-

SHIPPING MARKS

-

BARCODE VISUAL AND SCAN CHECK

-

PACKAGING WEIGHT AND DIMENSION

-

CARTON DROP TEST

Contact Us

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 227 189 7407

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.