First Article Inspection Services

Pro QC delivers independent First Article Inspections to confirm product specifications, ensure compliance, and improve manufacturing processes

As a quality control company, Pro QC provides First Article Inspection services in 100 countries. With over 40 years of experience, Pro QC is a trusted partner for businesses seeking to control quality at their factories and suppliers.

What is a First Article Inspection?

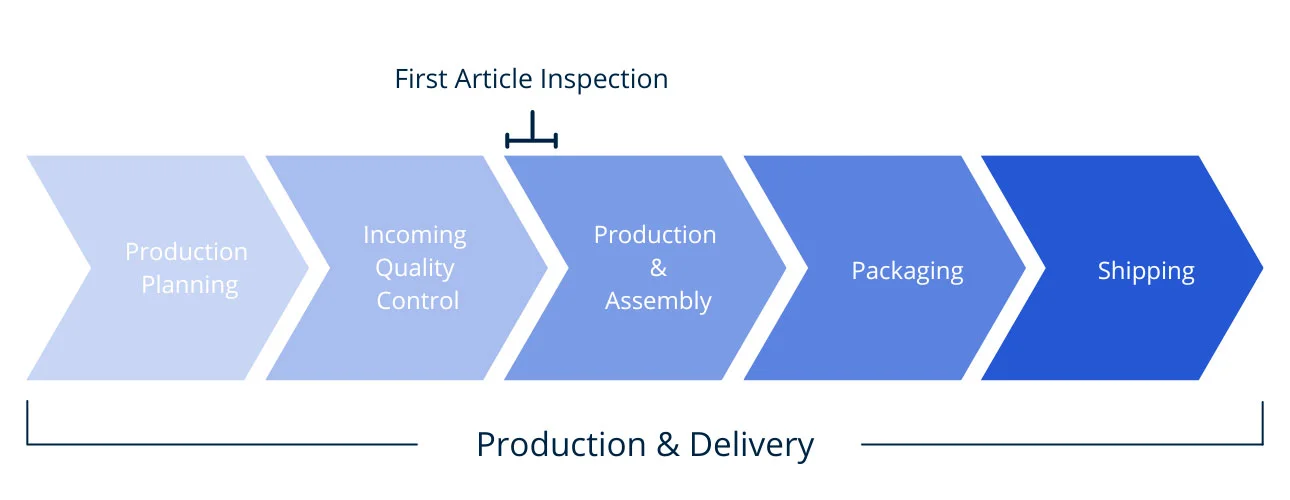

First Article Inspections (FAI), or Initial Production Inspections, are a critical step in ensuring that a product meets all the required specifications set forth by the customer. The purpose of FAI is to prove that a product’s design, manufacturing process, and quality control system can consistently produce parts to meet the customer’s requirements. A successful FAI will provide both the customer and manufacturer with the assurance that any part produced moving forward will meet tolerance levels and perform as expected. FAIs can be performed on both production and prototype parts.

Contact Us

Advantages of First Article Inspection Services

Ensuring that the final product meets all specified requirements

Identifying any potential problems with the manufacturing process

Allowing for modifications to be made to the manufacturing process before mass production begins

Providing a baseline against which future inspections can be performed

Pro QC’s First Article Inspection Services

As a leading third-party quality control service provider, Pro QC helps companies all over the world meet their quality control requirements. Our team of experienced inspectors, who understand the fundamentals of the production process, conduct all inspections according to established standards. Each inspector is carefully chosen depending on the product being inspected—a textiles specialist for garments, for instance; or an electrical engineer for electrical equipment inspection—so that all products meet their specified criteria.

Once assigned to First Article Inspection, our inspector controls product quality at the beginning of the production and uses a personalized checklist to examine each part for accuracy and compliance with customer requirements. Whenever any major or critical anomalies are found during an inspection, our customers are notified at once so corrective measures can be taken.

In a First Article Inspection (FAI), all aspects of the product’s design, manufacture, and assembly are inspected to ensure that they meet the requirements specified in the contract or engineering drawing. The inspectors will verify that the dimensions, tolerances, materials, finishes, and assembly processes are all in compliance with the requirements. In addition, they will evaluate the function of the product and its fitness for use. The results of the FAI are documented in a report which can be used to improve the manufacturing process and prevent problems in future production runs.

Ready to Improve Quality?

Get started with a free consultation and discover how our quality assurance services help to meet international standards and improve quality.

Pro QC’s First Article Inspection Reports

During a First Article Inspection service, our quality inspectors follow customized inspection checklists. They typically cover:

- Visual (workmanship) evaluation

- Functional (special testing) evaluation

- Measurement inspection

- Labeling/Packaging verification

- Photo documentation and reporting

Inspecting defects is the job of Pro QC’s quality control inspectors, who classify them into three categories: minor, major, and critical. A First Article Inspection report includes digital pictures and clients receive it within 24 hours of the service being completed. The results are either FAIL, PENDING, or PASS.

Key Differentiators

- Superior industry and technical expertise garnered since 1984

- Tailored quality solutions provided in 100 countries

- Specialized and qualified quality inspectors

- Detailed inspection reports delivered within 24 hours

- Experienced with over 30,000 products from all industries

Pro QC International

Our Service Reports

Detailed & Actionable

- Following International & Industry Standards

24 Hours

- Report Delivery forInspections

48-72 Hours

- Report Delivery for Audits

Pro QC Blog Posts & Related Offerings

Find out more about our related services by clicking below:

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 227 189 7407

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.