Supplier Development Solutions

Drive Continuous Improvement and Strengthen Supplier Performance with Pro QC

Supplier audits, compliance assessments, process audits, and product inspections are all detection methods for Pro QC to identify risks and issues at the factory.

The ultimate value Pro QC delivers is assisting our clients to resolve their problems and improve supplier competency. This effort will ultimately result in cost reductions and sustainable improvement.

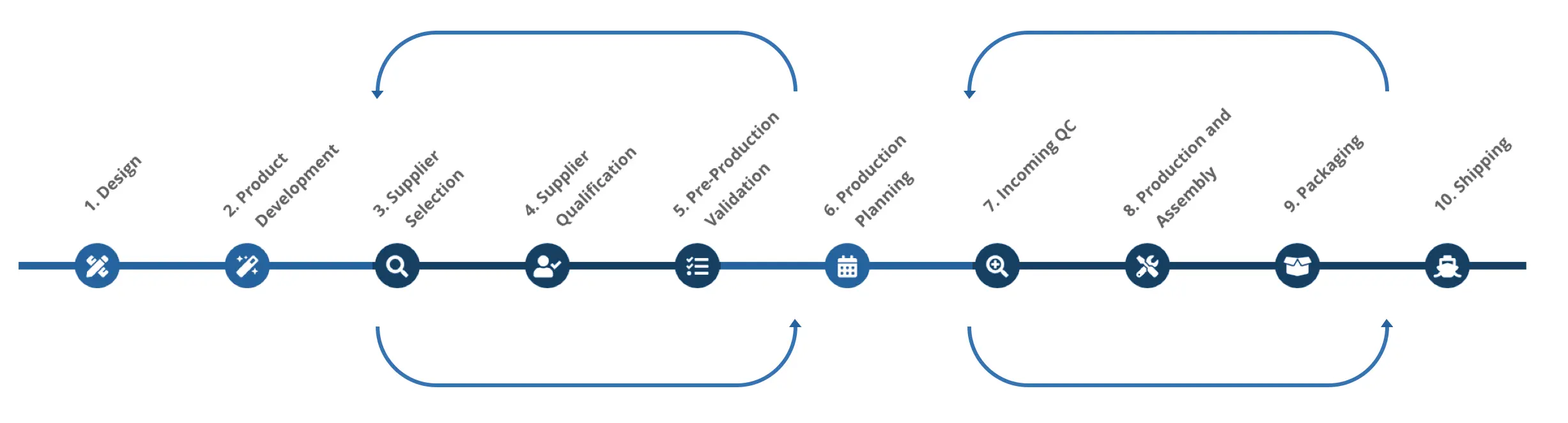

Click on Potential Supplier Development or Continuous Improvements in the image below to learn more about our corresponding solutions.

Contact Us

Potential Supplier Development

- Compliance improvement

- PPAP follow up

- CAPA Facilitation & Validation

- Process improvement

- Quality KPI improvement

- CAPA Facilitation & Validation

Potential Supplier Development

Risks and issues are often identified when onboarding a new supplier or working with an existing one on a New Product Development (NPD) process. Changes, corrective and preventive actions (CAPA), and training are often required to proactively minimize the potential failure or to re-qualify the production line.

This often requires intensive communications and QA follow-up between the buyer’s engineering team and the factory’s production team to ensure all risks are considered.

- Suppliers made changes without notifying their clients

- Suppliers lack the motivation or quality personnel to improve and implement system improvements

- Suppliers claim to have implemented improvement actions but are not validated for effectiveness

- Supplier actions only treat the symptoms of the problem rather than the root cause of the issues

- Clients do not have enough resources to follow up and validate the implemented actions

- Quality, Social, and Ethical Compliance Improvement

- PPAP Follow Up

- Supplier CAPA Facilitation

- Resident Supplier Quality Resourcing

Factory Continuous Improvement On the one hand, many of the suppliers our clients work with are small to medium size factories without the world-class quality management system or practices in place. On the other hand, some of our clients with a more established factory are always looking to improve their performance so they can sell their products into a more stringent sector. Whether the continuous improvement is triggered through a complaint or a proactive initiative, it calls for objective input and unbiased monitoring to facilitate the transformation.

- Suppliers lack the qualified quality personnel to drive changes or implement actions

- There is a lack of internal audits and quality assessments at the factory

- Factory assessments are biased

- There is a lack of systematic continuous improvement at the factory

- Lack of prioritization and objective monitoring of supplier’s improvement initiatives

- Quality System Improvement and Quality Tool Deployment

- Targeted Quality KPI Improvement

- Targeted Manufacturing Process Improvement

- Establishing Effective Production Control Plan

- Poka-Yoke Implementation

- Implementing Continuous Improvement

Supplier quality audits and supplier development initiatives always outweigh the potential cost of product recalls, safety compliance lawsuits, and marketing PR disasters

Sustainable Supplier Improvement with Pro QC’s Supplier Development Team

Pro QC understands improvement projects are fluid and every situation and scenario requires a bespoke approach. Our Supplier Development team consists of a diversified mix of Six Sigma Black Belt quality experts, certified auditors, and supplier quality engineers who are product domain experts.

Pro QC is ready to deploy a suitable project team to support your effort in:

Defining an approach to your challenges or improvement initiatives

Defining actionable milestones

Following up with suppliers

Resolving issues and validating CAPA

Annual audits and monitoring improvement progress

All supplier management projects aim to achieve long-term and sustainable improvement.

Ready to Improve Supplier Performance?

Pro QC’s Core Value Proposition

The Supplier Development consulting services provided by Pro QC aim to help our client manage their supplier risk and reduce their Cost of Poor Quality. This ultimately translates into an improved profit margin and enhanced brand reputation.

To discuss how we can help you manage your suppliers and ensure that they meet all performance requirements, contact us today.

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 227 189 7407

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.