Quality Solutions in Mexico

Pro QC International provides quality solutions throughout Mexico

With over four decades of experience, we develop and manage a comprehensive network of skilled and knowledgeable professionals throughout the region and globally who are flexible to assist with both short and long-term projects.

From our testing laboratory and offices in Monterrey, we represent clients located in the region that are sourcing abroad and benefit from our cost-effective expertise where suppliers are located. We also represent clients located outside of the region that want on-site, local expertise to test products or evaluate suppliers and/or shipments in Mexico.

Our quality engineers and auditors offer applicable industry experience related to medical devices, electronics, automotive, consumer retail, textiles/garments, and more. Available with little notice, our resources are deployed where you need them, when you need them.

Whether it’s assisting with identifying and developing suppliers, or evaluating product quality on-site or in our ISO 17025 certified testing lab in Monterrey, we offer a partnered approach to solutions.

Our Quality Assurance (QA) and Quality Control (QC) services in Mexico include:

Our Services in Mexico

- Quality Solutions Overview

- Quality Resources

- Supplier Qualification & Development

- Product Quality Solutions

Our Local Office

Contact Us

Our Quality Control Coverage in Mexico

Our Quality Control Services in Mexico

Click on the current stage of your sourcing or product development journey below to explore our related quality solutions.

1. New Product Development

New product development lays the foundation for strategic sourcing. Prototyping is crucial to validate that the supplier understands the client’s requirements.

Pro QC inspections validate the new parts while our supplier development services align quality expectations with suppliers and strengthen their ability to meet quality requirements and reduce time to market.

Pro QC’s Quality Solutions:

First Article Inspection (FAI)

Supplier Development Services

Resident Supplier Quality Resourcing

Supplier Risks & Challenges:

Poor communication of technical details between buyers and factories

Misalignment of product specifications and critical design requirements among buyers, suppliers, and factory production teams

Inadequate consideration of advanced product quality planning

Challenges when transitioning from prototype suppliers to mass-manufacturing suppliers

Misalignment on design and engineering revisions

2. Supplier Selection

Once the component specifications are defined, the procurement department identifies a list of suitable suppliers that can potentially meet their capability, cost, capacity, and quality requirements.

Pro QC offers a range of supplier due diligence and supplier evaluation support. Our experts visit suppliers to assess their capabilities, mitigate the risk of scams, overpromises, and miscommunication, and validate their credentials, trustworthiness, and financial stability.

Pro QC’s Quality Solutions:

Supplier Quality Audits

QHSE Audits

ESG Audits

Onsite Supplier Verification

Financial Credit Check

Supplier Risks & Challenges:

Lack of experience and due diligence in new supplier region

Communication challenges

Concern about supplier scams

Low confidence supplier’s trustworthiness

Concerns over supplier’s financial viability

3. Supplier Qualification

A world-class organization usually has a comprehensive supplier qualification program to identify and mitigate the risks associated with quality, safety, on-time delivery, cost, and compliance.

Pro QC establishes a global audit program to systematically onboard new suppliers, categorize their risk levels, and establish a reaction plan based on the supplier’s performance on quality systems, environmental management, and social and ethical compliance.

Pro QC’s Quality Solutions:

Global Supplier Audit Programs

Supplier Quality Audit for Potential Suppliers

Quality Management System Audit

Social & Ethical Audits

Supply Chain Security Audit

Environmental Audit

Supplier Risks & Challenges:

Suppliers are not as capable as they initially claimed

Supplier lacks effective and systematic quality assurance practice

Supplier is ISO 9001 certified, but the underlying principles are not implemented in practice

Mass production quality does not match prototype quality

Buyers want to sell to big retailers, but their suppliers do not yet comply with the retailer’s supplier code of conduct

Supplier violation on labor law, ethical and environmental compliances

Goods held in customs due to supply chain security malpractice

4. Pre-Production Validation

Before commencing volume production, it is crucial to validate that the equipment, staffing, production methods, capacity, and quality control plan are in place for each product line.

Pro QC offers on-site quality support to prevent and reduce the potential cost of poor quality (COPQ) and risk, ensuring a smooth transition from product development to mass production.

Pro QC’s Quality Solutions:

Engineering Build (EB) and Quality Build (QB) Audit

First Article Inspection (FAI)

APQP/PPAP Audit

Manufacturing Process Audit or VDA 6.3 Process Audit

Resident Supplier Quality Resourcing

Supplier Risks & Challenges:

Factory not ready for mass production

Shipment delays due to critical failure, poor quality, and resource constraints

An exponential increase in defective products

Product recall

High Cost of Poor Quality

An exponential increase in the cost of change after mass production commences

5. Production Planning

Production planning ensures that the supplier has sufficient raw materials, components, and staff and that other outsourced processes meet the specified schedule.

Pro QC offers assistance in timely supplier communication, onsite visits, and daily or weekly monitoring reports. This minimizes the risks of delays from ineffective procurement planning, staff shortages, or sub-supplier mismanagement.

Pro QC’s Quality Solutions:

Order Expediting

Resident Supplier Quality Resourcing

Supplier Risks & Challenges:

Production delay due to poor material procurement planning

Production delay due to inadequate production staffing

Poor sub-supplier management

6. Incoming Quality Control

Incoming inspection reflects a factory's commitment to quality control from the outset. Understanding how a factory manages its incoming material and its supply chain is a very good indication of its commitment to quality.

Pro QC quality solutions address issues such as defect acceptance, material substitutions, and component decay due to poor practices or storage conditions.

Pro QC’s Quality Solutions:

Incoming Inspection

In-Process Inspection

Manufacturing Process Audit or VDA 6.3 Process Audit

Supplier Risks & Challenges:

The factory does not manage the quality of its supply chain or is poor at supplier management

Suppliers turn a blind eye to defective components during incoming and still use them for production and assembly

Using sub-standard material or components (e.g., lower-quality fabric than required)

Substituting lower-cost alternatives for product components (e.g., cheaper electronic components in a mobile phone)

“Quality fade” where suppliers make small, gradual substitutions in materials and components over time

Bulk material ordered by the supplier degrades over time due to poor storage conditions

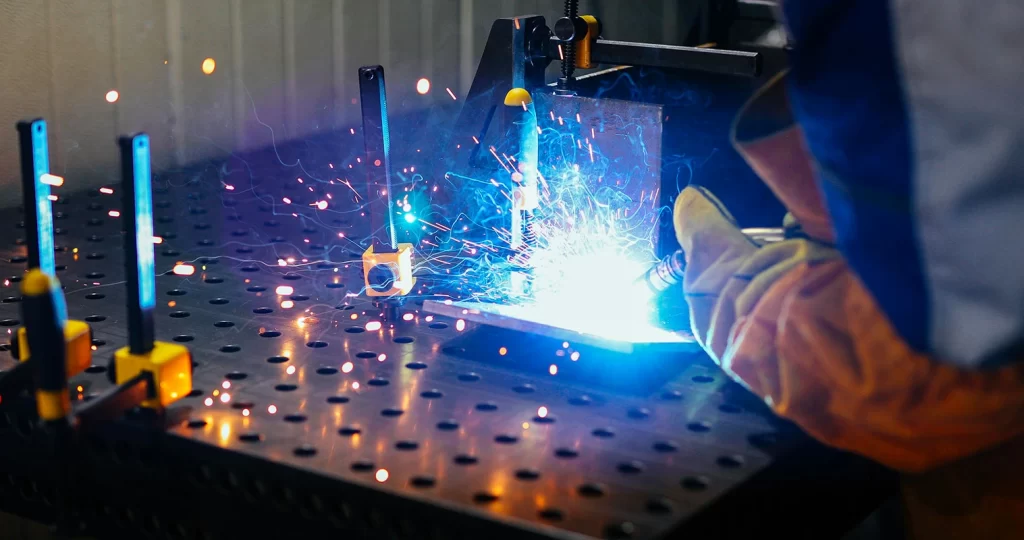

7. Production & Assembly

Many things can go wrong during mass production due to machine failure, lack of process control, and operator mistakes. While it is normal for defects to occur, these defects must be detected and contained.

Pro QC offers a range of support to verify control plan adherence, early defect detection, quality improvement, and issue resolution through monitoring, investigations, and CAPA validation.

Pro QC’s Quality Solutions:

First Article Inspection (FAI)

In-Process Inspection

Manufacturing Process Improvement

Quality/Root Cause Investigation (8D)

CAPA Verification

Order Expediting

End-Of-Line Testing & inspection

Resident Supplier Quality Resourcing

Supplier Risks & Challenges:

Operators are not producing according to the production control plan

Supplier is under pressure to ship goods, turning a blind eye to defective components

Lack of quality staff to enforce quality control

Poor control of re-worked material/product

Mistakes made by temporary, untrained staff/operators

Communication breakdown when the supplier is under pressure

8. Outgoing QC & Shipping

The smallest aesthetic defect on the packaging or missing components can lead to customer returns, while a misplaced label may result in compliance issues. Outgoing Quality Control is the last line of defense before products are properly loaded into containers for shipment.

Pro QC offers pre-shipment inspections and end-of-line testing to ensure your products meet your quality requirements and reduce the chance of returns or re-work.

Pro QC’s Quality Solutions:

Manufacturing Process Audit

Poka-Yoke Implementation

Pre-Shipment Inspection

End-Of-Line Testing & inspection

Container Loading Supervision

C-TPAT Audit

Supplier Risks & Challenges:

Products are poorly packaged

Human mistakes and missing components lead to customer returns

Wrong labeling leads to compliance issues and significant re-work

Rough handling of goods during container loading by the factory or outsourced warehouse, leading to damaged product

Poor container loading leads to product damage during transit

Our Quality Control Services in Mexico

Supplier Qualification & Development

At Pro QC, we also work closely with clients and their suppliers to improve their system, processes and manufacturing capabilities.

Product Quality Solutions

Pro QC offers the services detailed below as well as the possibility to schedule service requests and access our reports through our secure database.

Quality Resources

Quality Control (QC) Product Inspections

- First article

- In-process

- Pre-shipment

- Metrology

Pro QC’s quality engineers inspect products at different stages in the production process. ANSI Z1.4 sampling is generally employed to evaluate workmanship, functionality, packaging, labeling, etc. We review and check against existing client specifications and can assist in the development of criteria as necessary.

Quality inspectors use Pro QC’s standard report forms, or we can use those that are provided by the client. Detailed photos are provided, with all information available online within 24 hours of completion.

Pro QC’s local resources often reduce costly travel and/or eliminate the need to allocate internal resources. Our quality professionals are on-site representing client interests and evaluating product to further ensure it meets expectations.

Our inspectors have experience in the following industries:

- Automotive

- Hardware

- Housewares

- Furniture

- Energy / Solar

- Consumer Electronics

- Textiles & Garments

- NACE Coating Inspection Program (CIP) Certified Level I, II, and III

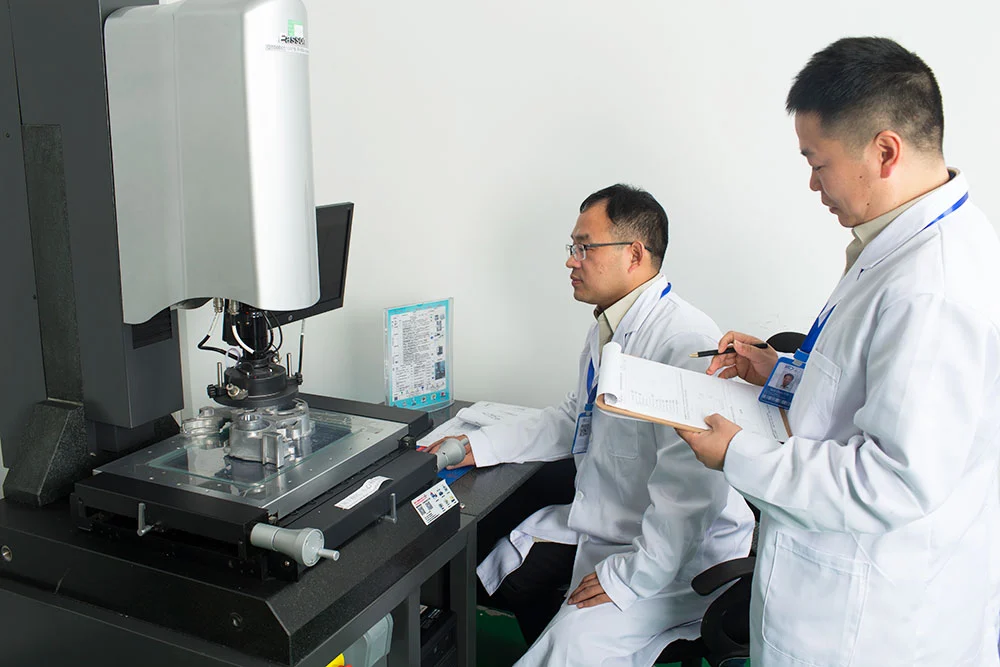

ISO/IEC 17025 Product Testing

Pro QC’s testing laboratory in Monterrey is accredited by ISO/IEC 17025 and EMA (Entidad Mexicana de Acreditación). The lab specializes in Norma Oficial Mexicana NOM-046-SCFI evaluations of measuring instruments (tape measures), but offers additional general capabilities for other products as well.

Samples can be collected on-site during inspections or as requested.

Our testing services include, but are not limited to, the following:

- Metrology (CMM, etc.)

- Lifecycle

- Performance

- Functionality

Where services are not provided, we work with trusted partners to extend competitive pricing and seamless management.

Supplier Qualification & Development

Supplier Qualification

When new suppliers are considered, we offer an Initial Supplier Evaluation that provides a one-day on-site assessment covering the primary QMS components and general capabilities.

- Management

- Engineering

- Quality Control / Quality Assurance

- Incoming Receiving Inspection

- Manufacturing

- Packaging

- Non-Conforming Materials

- Corrective Action

- Inspection & Test Equipment

More in-depth assessments related to the industry, such as IATF 16949 or ISO 13485 are also available. Social accountability (SA8000), security (C-TPAT), and other components can be incorporated as well.

Example reports are found here: https://proqc.com/services/sample-reports/.

Pro QC can also represent you on-site to evaluate a supplier using your organization’s existing qualification criteria and reporting requirements.

Supplier Development

At Pro QC, we work with clients and their suppliers to improve their system, processes and/or product manufacturing capabilities. Example projects include:

Vendor (Supply Chain) Compliance

We assist to ensure supplier compliance with final audits required by major retailers and/or associations. Example compliance requirements we work with include Walmart, BJ’s, Lowe’s, Home Depot, Dick’s Sporting Goods, etc.

Continuous Improvement

We conduct regular 80/20 evaluations of QC data with continuous improvement initiatives developed and executed.

Certification Preparation

We assist to ensure compliance prior to the final audit. Applicable industry standards include IATF 16949, ISO 13485, ISO 9001, etc.

Contact us for additional information regarding our customized approach to improving your supplier’s performance.

Product Quality Solutions

Pro QC Blog Posts & Related Offerings

Find out more about our related services by clicking below:

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 227 189 7407

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.