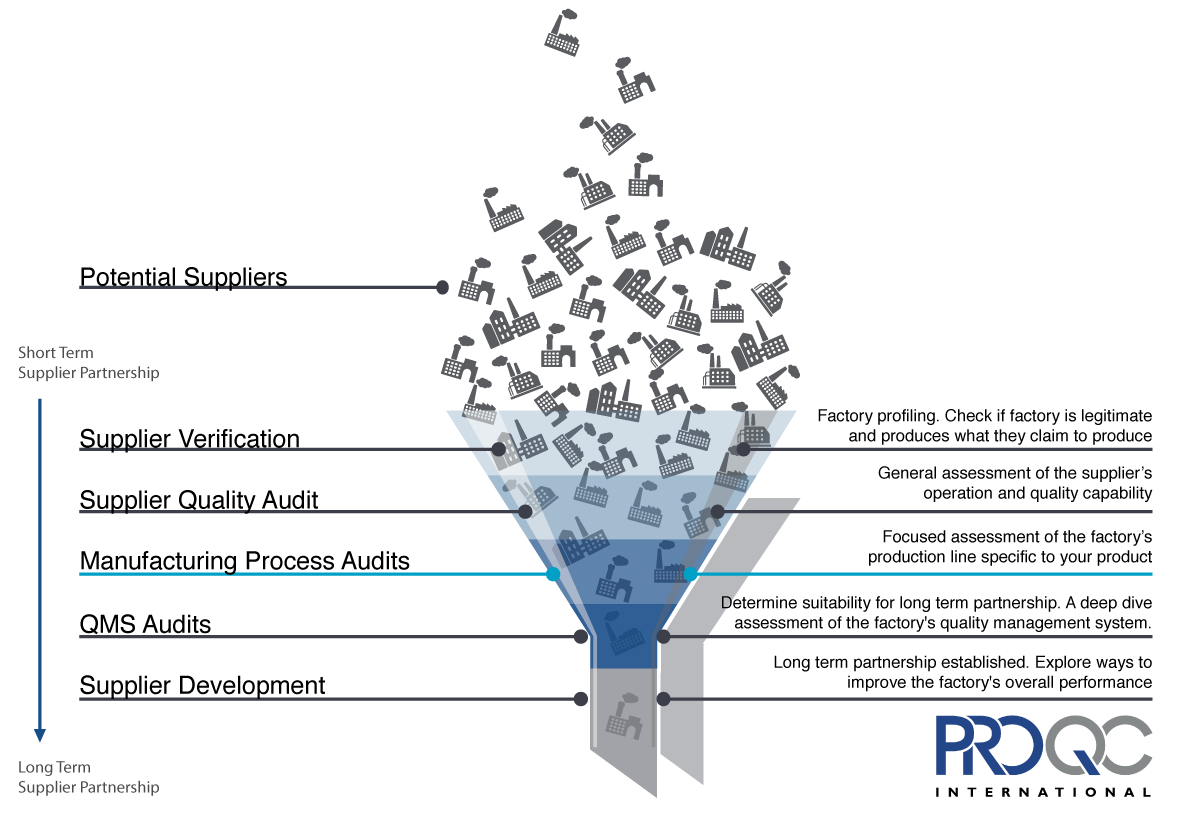

Manufacturing Process Audits

Pro QC evaluates supplier production lines to identify risks, improve efficiency, and ensure consistent product quality

Pro QC International is a global quality assurance company that offers manufacturing process audit solutions across five continents. We help qualify suppliers, validate production line processes, and investigate the root causes of defects.

In our experience, the quality performance of a good factory varies by production lines due to multiple factors such as people, equipment, materials, methods, production environment, and a plethora of other factors.

Pro QC’s Manufacturing Process Audit focuses on assessing the specific production line that is or will be producing your product. The assessment will assess the quality practice of a product from incoming material, through to every single stage of the production process, including material handling, in-process quality control activities, outgoing QA, and warehousing.

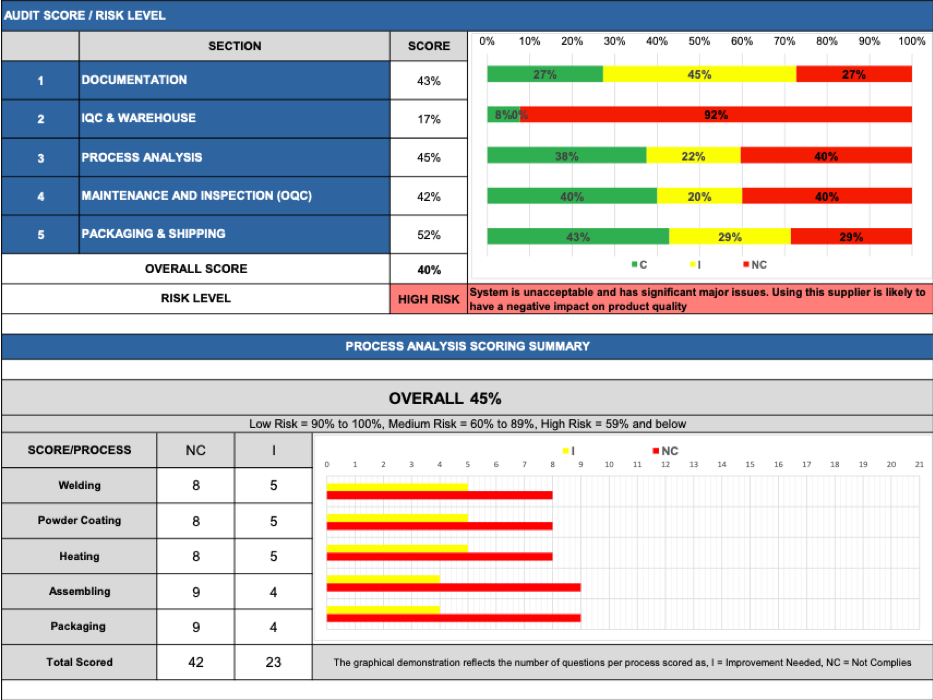

The outcome of the Manufacturing Process Audit is a thorough manufacturing audit report which includes a risk-based process control analysis of the factory. The report consists of Pro QC’s risk recommendations, on-site observations, performance scores, and high-resolution photos. The report will be used by supply chain and quality professionals to make better-informed decisions about the finer details of their supplier for factory performance.

Contact Us

Manufacturing process audits provide valuable insights that can lead to improved process optimization, superior product quality and minimized risk.

When is a Manufacturing Process Audit Required?

Our clients often choose our Manufacturing Process Audit service for four reasons:

1. Supplier Qualification

Most companies have their own set of supplier onboarding processes and criteria to prequalify and manage their suppliers. In tandem with the internal approach, many clients use our Production Process Audit as part of the onboarding assessment. This assessment provides a deeper understanding of a specific production or assembly line of their product and another set of data points to consider before placing a purchase order.

This is especially useful for large orders of technical parts or assembly-intensive products where identifying and subsequently mitigating specific production risks is paramount.

2. Preproduction validation

Before entering mass production, conducting a thorough manufacturing process audit is paramount. By scrutinizing each step of the production process, manufacturers can identify potential flaws, streamline operations, and prevent costly deviations from standards. Production Process audits also play a pivotal role in upholding regulatory compliance, ensuring that products meet industry guidelines.

This meticulous process evaluation ensures that production processes align with defined standards, preventing defects, optimizing operations, and mitigating risks. By identifying these problems and risks before mass production, buyers can prevent defects from being produced in the hundreds of thousands, thereby reducing the cost of risk and poor quality.

3. Root Cause Investigation

Suppliers tend to perform well and produce according to specifications in the early days of the buyer-factory relationship. Over time, key personnel may change, operators come and go, tools and equipment wear out, processes drift and, as a result, the quality of the product deteriorates. This may manifest itself in any number of issues including delayed shipping, unanswered emails or complaints, receipt of defective products, and even field failures.

At the first sign of any field failure or receipt of a defective product, our client triggers an 8D and engages Pro QC to investigate the root cause of the quality defect. Pro QC will send our auditors on-site to analyze the problem through a thorough Manufacturing Process Audit. This risk-based analysis of factory process controls identifies the production bottlenecks, sources of defects, and activities that are poorly executed or lack standard quality control. We then report back to the client with the results and recommended actions, including dates for a Pro QC follow-up visit.

4. Continuous Improvement & Sustainable Performance

Efficiency gains are another noteworthy benefit. Buyers and manufacturers can implement improvements that enhance resource allocation and reduce production costs by pinpointing inefficiencies and bottlenecks through manufacturing process audits.

Moreover, a manufacturing process audit fosters continuous improvement. Insights gleaned from audits guide the adoption of best practices, innovative technologies, and optimized methodologies.

Incorporating audits within preproduction activities leads to an all-encompassing approach to quality control, bolstering product excellence and customer satisfaction. Ultimately, the manufacturing process audit serves as an invaluable tool for manufacturers to uphold standards, minimize risks, and elevate their production processes to new heights of success.

Manufacturing Process Audit Assessment Criteria and Report

We understand that every product and component has its own specific production process and corresponding criteria, and we treat each client challenge as unique. That said, Pro QC has developed a unique manufacturing process audit framework and approach that can be applied across most industries, production, and product types.

Pro QC’s manufacturing auditors and experts will work with your team to tailor our manufacturing audit checklist to your specific production line and dive deep into your quality problems.

- Technical Documentation

- Incoming Quality Control (IQC) & Warehousing

- Process Analysis (IPQC)

- Process Input

- Process Management

- Personnel Resources

- Material Resources

- Process Efficiency

- Process output & results

- Maintenance and Inspections (OQC)

- Packaging Shipping

Pro QC assigns process auditors and quality engineers with relevant experience in the industry, product category, and processes to perform the on-site Production Process Audit assessment.

The resulting report gives our client a snapshot of the risk profile of their production line and helps pinpoint areas with the highest room for improvements.

Manufacturing process audits are an essential tool for companies seeking to maintain efficiency and competitiveness in their industry.

Pro QC International

Our Service Reports

Detailed & Actionable

- Following International & Industry Standards

24 Hours

- Report Delivery forInspections

48-72 Hours

- Report Delivery for Audits

Download Sample Reports

Pro QC Blog Posts & Related Offerings

Find out more about our related services by clicking below:

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 227 189 7407

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.