Pipelines Inspection Services

Pro QC International ensures pipeline quality and safety with expert third-party inspections, welding checks, and non-destructive testing worldwide

Pro QC International helps companies ensure line pipe integrity and quality with third-party pipeline inspection services including non-destructive testing (NDT) and coating and welding inspections in the Americas, Europe, Asia, Middle East, and Africa.

The quality and reliability of line pipes and pipelines are essential to serve global markets and prevent environmental damage. The inherent business risks and ever-tightening regulations make it critical for companies to conduct thorough inspections and assessments from the production of new pipes to the installation and maintenance of existing equipment.

Corrosion, porosity, defective welding, and cracks are the causes of most oil and gas pipeline failures. These defects and failure modes must be identified, assessed, and corrected proactively with targeted, expert methods.

Pro QC International is a trusted global quality assurance provider with over four decades of experience in the industry. Our piping engineers and quality consultants conduct pipeline inspections across the globe. We control line pipe quality with independent non-destructive testing (NDT), pre-shipment inspections (PSI), coating inspection, welding inspections, and other related services. Pro QC has a proven track record of helping companies establish their quality control strategy and protect their interests with quality solutions tailored to each business need. In all aspects of our work, we follow Pro QC’s values: trustworthiness, excellence, and passion.

Contact Us

Pro QC International helps companies guarantee the integrity and quality of pipelines through third-party inspection services.

Our Third-Party Pipeline Inspection Services

The need for pipeline integrity services is developing in tandem with the rapid construction of new pipelines and the replacement of aging pipelines. Pro QC’s pipeline inspection services aim to answer the needs of the industry and cover the following types of pipes:

- Small diameter high-pressure natural gas pipeline (SML steel pipe)

- High-frequency straight seam welding (ERW steel pipe)

- Spiral submerged arc (SSAW steel pipe)

- Straight seam submerged arc (LSAW steel pipe)

- Cast iron pipes

- Plastic pipes

- Concrete pipes

- And more

As a third-party pipeline inspection company, we deploy our expertise to a wide range of comprehensive line pipe inspection services as outlined below:

- In-Process Inspections

- Quality Inspection of Final Products (Pre-Shipment Inspection)

- Documentation Review

- Visual Inspection

- Dimension Inspection

- Storing & Handling Inspection

- Packing & Loading Inspection

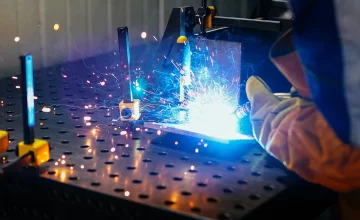

- Welding Inspection

- Hydrostatic Testing

- Non-Destructive Testing (NDT)

- Penetrant Testing (PT)

- Magnetic Testing (MT)

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Coating Inspection

- Painting Inspection

- Witness Inspection

- Valves Inspection

- Fittings Inspection

Our Team of Pipeline Inspection Experts

Pro QC deploys local quality engineers for long and short-term projects to support customers in evaluating equipment integrity with NDT and third-party pipeline inspections in the USA, Canada, Mexico, Brazil, Argentina, Peru, Russia, Italy, UK, France, Germany, Spain, Poland, Norway, Czechia, Romania, Ukraine, Greece, Bulgaria, the Netherlands, Hungary, Finland, Turkey, UAE, Saudi Arabia, Jordan, Algeria, Morocco, South Africa, Kenya, Egypt, Tunisia, China, Taiwan, Korea, India, Indonesia, Malaysia, Thailand, Vietnam, Kazakhstan, Azerbaijan, and many more countries.

Our piping, welding, and coating inspectors are experienced and qualified with the following standards: ASME, ASTM, CAN/CSA, IEC, ISO, ANSI, API (e.g., API 570), ARAMCO QM, NACE, FROSIO, AWS, AS/NZS and more. Pro QC’s network includes level I, II, and III qualified engineers with the requisite certifications.

Our Oil and Gas Pipeline Inspection Services

The oil and gas industry relies on extensive pipeline networks to transport crude oil, refined products, and natural gas efficiently and safely. Ensuring pipeline integrity is critical to preventing leaks, corrosion, and structural failures that could result in severe environmental, economic, and safety consequences.

Pro QC International provides comprehensive oil and gas pipeline inspection services to help companies maintain compliance with international standards, industry best practices, and local regulations. Our third-party inspection solutions cover every stage of the pipeline lifecycle, from material procurement and fabrication to construction, installation, and in-service inspections.

Oil and Gas Pipeline Inspection Capabilities

Pro QC’s oil and gas pipeline inspection services include:

- Material and Manufacturing Inspection: Ensuring compliance with industry specifications for raw materials, welds, and coatings through independent verification.

- Pipeline Construction Inspection: Overseeing welding procedures, joint coating applications, and proper alignment during pipeline assembly.

- In-Service Inspection & Maintenance Assessment: Evaluating the integrity of aging pipelines through non-destructive testing (NDT) techniques.

- Corrosion Detection & Prevention: Identifying early signs of corrosion and applying protective measures.

- Hydrostatic Testing & Leak Detection: Verifying the structural integrity of pipelines under pressure to ensure safe operations.

Why partner with Pro QC International for pipeline industry quality solutions?

Pro QC International

Our Service Reports

Detailed & Actionable

- Following International & Industry Standards

24 Hours

- Report Delivery forInspections

48-72 Hours

- Report Delivery for Audits

Why Pro QC International?

Advanced Quality Analysis

Industry-leading quality dashboard, analytics, and supplier performance analysis tools and framework

Expert-Led Solutions

Technical expert advice from first contact ensures reliable solutions are executed with precision

Qualified Resources

Resource transparency and the right qualifications safeguard your interests on every project at every supplier

Globally Aligned Operations

Operational processes are optimized and aligned for a seamless cross-regional experience

Stringent Technical Oversight

Meticulous technical preparation, guidance throughout the engagement, and report review by senior engineers

Single Contact Point

A single contact point for quality services globally simplifies your supply chain

Stability and Expertise

Founded in 1984, over 40 years of experience make Pro QC a trustworthy and dependable quality partner

Pro QC Blog Posts & Related Offerings

Find out more about our related services by clicking below:

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 227 189 7407

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.