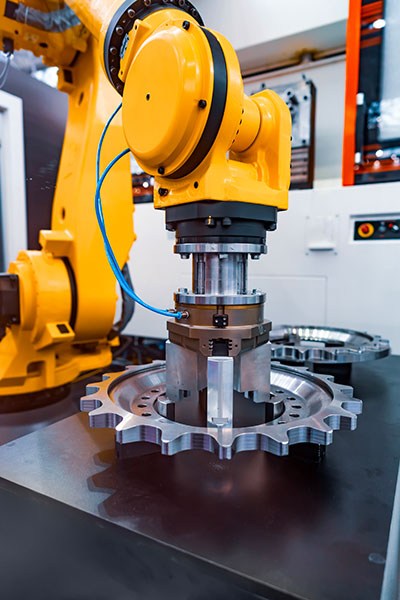

Quality Assurance and Quality Control Services for Industrial machinery

Since 1984, Pro QC has supported manufacturers and buyers with inspections, audits, and supplier management to ensure machinery meets international standards

Quality assurance and quality control are important parts of the industrial machinery industry, and Pro QC International has been providing these services since 1984.

The Industrial machinery industry is constantly evolving and it’s important to have the right equipment and quality to meet market expectations. Pro QC International assists buyers and suppliers with a wide range of quality assurance and quality control services designed for the needs of the industrial machinery industry. We are dedicated to ensuring quality across the Industrial machinery industry as well as creating a trustful environment between buyers and sellers.

Industrial machinery firms cherish honesty, transparency, and control in their relationships with suppliers. Depending on their experience, they may partner closely with a manufacturer for an all-in-one solution. Pro QC will also improve this relationship by supplying them with a high-quality supplier management suite that covers every step of the production process. When it comes to quality assurance services, Pro QC is a trusted partner for success. Our team help solves non-conformities during the production process and ensures compliance with quality management standards. Whether companies are looking to improve their factory performance or control product quality, our expertise and reliability will be invaluable to them.

In addition to being a go-to source for quality control services, Pro QC offers diverse geographic coverage. We operate in 100 countries, including China, Japan, Taiwan, Korea, Vietnam, Thailand, India, Indonesia, Turkey, Egypt, UAE, Spain, Portugal, France, Italy, Switzerland, Germany, Belgium, the Netherlands, the United Kingdom, Poland, Czechia, Slovakia, Slovenia, Serbia, Sweden, Norway, Denmark, Finland, Romania, Bulgaria, Canada, the United States, Mexico, Brazil, Colombia, and many more countries.

Contact Us

Ready to Improve Quality?

Get started with a free consultation and discover how our quality assurance services help to meet international standards and improve quality

Our Solutions

For over four decades, Pro QC has helped businesses and customers create high-quality industrial machinery. We have tailored our quality assurance and quality control solutions to cover each major industrial machinery industry sector, including:

- Packaging Machinery

- Food Processing Equipment

- Plastics Processing Machinery

- Metal Forming Machine Tools

- Woodworking Machines

- Printing Machinery

- Semiconductor Machinery

- Chemical Processing Machinery

- Glass Making Machinery

- Tannery Machinery

- Textile Making Machinery

- Others

Quality Assurance & Quality Control for Industrial Machinery

Manufacturing Audits and Advisory

Take advantage of our end-to-end comprehensive approach to improve your supply chain performance.

- Manufacturing Process Audits

- Process Improvement

- Production Capacity Analysis (Run & Rate)

- Quality Investigation (root cause investigation of a defective product)

- Root Cause Analysis

- Corrective Action Follow-Up

- Process Failure Mode Effects Analysis (PFMEA)

- Continuous Improvement

Supplier and Factory audits

Pro QC provides a broad range of factory audit solutions to the industrial machinery industry:

- Supplier Verification

- Supplier Quality Audits

- ISO 9001 Quality Management System Audits

- ISO 14001 Environmental Management System Audits

- ISO 45001 Management Systems of Occupational Health and Safety Audits

- Social Compliance Audits

- Supply Chain Security Audits

- Combined Audits

Industrial Machinery Inspection Services

Our quality control inspections for industrial machinery include:

- First-Article Inspections (FAI) are performed prior to mass production. Product properties are measured and compared with specifications to verify quality matches.

- In-Process Inspections (IPI) ensure that the processes and techniques used to manufacture machinery are followed.

- Pre-Shipment Inspections (PSI) vverify the conformity of machinery to specifications before shipping. Inspectors evaluate workmanship, functionality, packaging, labeling, and other criteria as required.

- Container Loading Supervision (CLS) ensures that proper methods are employed during product loading, and counts are verified on-site.

- Sorting services are used to inspect production and detect quality issues or perform rework operations.

- Factory Acceptance Test (FAT)

- Welding Inspections

Supplier Management

Pro QC’s Supplier Management Solutions enhance compliance and performance of the entire supplier portfolio by:

- Performing an on-site risk assessment

- Establishing a corrective action plan

- Verifying corrective action implementation through detailed follow-up activities

- Scheduling subsequent annual visits based on supplier risk level

- Providing a supplier portfolio dashboard and performance analysis

Our supplier management team will create a customized checklist that meets even the most exacting requirements. The supplier management service is particularly suitable for small QA teams with a large supplier base across the globe. Pro QC assists these teams in investigating and resolving compliance and quality issues in a timely and cost-effective manner.

Pro QC International

Our Service Reports

Detailed & Actionable

- Following International & Industry Standards

24 Hours

- Report Delivery forInspections

48-72 Hours

- Report Delivery for Audits

Why Pro QC International?

Advanced Quality Analysis

Industry-leading quality dashboard, analytics, and supplier performance analysis tools and framework

Expert-Led Solutions

Pro QC has overseen successful supplier transformation projects which has helped companies from the industrial machinery industry to achieve their quality goals

Qualified Resources

Resource transparency and the right qualifications safeguard your interests on every project at every supplier

Globally Aligned Operations

Pro QC has agile teams of engineers in 100 countries ready to meet your quality assurance needs for projects ranging from a quality control inspection of industrial machinery to a comprehensive QMS audit

Stringent Technical Oversight

Meticulous technical preparation, guidance throughout the engagement, and report review by senior engineers

Single Contact Point

A single contact point for quality services globally simplifies your supply chain

Stability and Expertise

Founded in 1984, over 40 years of experience make Pro QC a trustworthy and dependable quality partner

Pro QC Blog Posts & Related Offerings

Find out more about our related services by clicking below:

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 227 189 7407

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.