Quality Assurance and Quality Control Services for Electric Cars

Pro QC helps EV manufacturers ensure safety, compliance, and performance with global inspections and audits

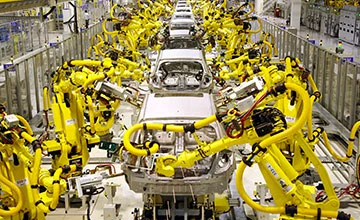

For over 40 years, Pro QC International has been a trusted partner in the world of quality control services. With the electric vehicle (EV) industry booming at an unprecedented rate, the need for meticulous quality assurance and quality control is critical. We have been providing our expertise to the EV sector, ensuring that the rapid strides in technology and innovation are matched by uncompromising quality standards.

Commitment to Customers

At Pro QC International, we are committed to delivering outstanding customer satisfaction. We understand the unique quality control needs of the electric vehicle market, and we are dedicated to meeting these needs with precision and excellence. Our quality control services for electric cars are designed to align with global standards, providing manufacturers with the assurance that their products meet all performance and safety requirements. We realize that every client has specific needs and expectations, and we tailor our services accordingly to safeguard their interests.

Services Overview

Our solutions are comprehensive and cater to all aspects of electric car manufacturing. We provide thorough quality control inspections for electric cars and their components to detect and rectify quality issues at the earliest stages. Through our supplier verification solution, we ensure the reliability of new partners for electric vehicle parts manufacturing.

We also conduct thorough factory audits to assess and improve the manufacturing process’s quality and efficiency. Our QMS audits, guided by ISO 9001, IATF 16949 and VDA 6.3 standards, ensure that quality management systems are up to the mark, fostering a culture of continuous improvement. Recognizing the importance of environmental responsibility in the electric vehicle sector, we facilitate ISO 14001 certification preparation, helping businesses minimize their environmental impact.

Global Reach

Pro QC International’s services extend across the globe, covering the majority of electric cars and electric vehicle parts manufacturing regions. Our quality control experts are present in numerous countries, including the United States, China, Taiwan, Japan, South Korea, Thailand, Malaysia, Poland, Hungary, France, the United Kingdom, Spain, Italy, Sweden, Germany, Canada, Mexico, and many more. Our expansive presence enables us to provide our clients with timely and efficient services, no matter where their operations are located.

Contact Us

Ready to Improve Quality?

Effective quality control helps manufacturers minimize the risk of defects and ensure that EVs meet or exceed safety standards.

Quality Control Applications for Electric Cars

Our quality control services for electric cars are comprehensive, covering various critical components and systems, such as:

- Battery Systems

- Power Inverters

- Charging Ports

- Onboard chargers

- Cooling & Heating systems

- Electrically-Powered Accessories

- Electric Motors

- AC/DC Motors

- Charging Infrastructure

- Safety Features

- Interiors and Exteriors

- Mechanical Components

- Brake Systems

- Tires & Wheels

- And many more EV parts…

At Pro QC International, our dedication to quality is unwavering. With our deep understanding of the electric vehicle industry, extensive experience, and global presence, we strive to provide the best quality control services for electric cars, helping companies drive toward a safer, cleaner, and more efficient future.

Electric Vehicle Standards

ISO 6469-3:2021 Standard for Electric Road Vehicles. This standard covers test procedures and criteria for voltage class B electric vehicles. It provides electrical safety requirements for the protection of persons against electric shock and thermal incidents. ISO 6469 is a wide-ranging standard, over three parts, which provides:

- Safety specifications for rechargeable energy storage systems for EVs.

- Functional and operational safety means.

- Specific protection against electrical hazards.

BS EN IEC 61851-1 outlines general requirements for EV conductive charging systems. The standard covers characteristics, specifications and safety requirements for the power supply, and the connection between this charging equipment and the vehicle.

IEC TS 61980-2 gives requirements around the communication between vehicle and wireless power transfer (WPT) systems connected to the supply network.

BS EN 62196-2, which provides requirements for plugs, socket outlets, vehicle connectors and vehicle inlets in terms of dimensional compatibility and interchangeability requirements for pin and contact-tube accessories.

BS EN ISO 15118-3 provides requirements for a physical vehicle-to-grid communication interface, as well as data link requirements and basic signaling.

BS EN ISO 15118-8 offers requirements for wireless communication interfaces.

Our Quality Assurance and Quality Control Solutions for Electric Vehicles

Electric Car Quality Control Inspections

When it comes to electric vehicles, precision and quality are crucial. Our dedicated team dives deep into evaluating each component of an electric car to ensure it not only meets but exceeds industry standards. We are committed to guaranteeing that every EV part upholds the highest benchmarks of excellence. Dive into our comprehensive range of quality control inspections for electric cars:

Supplier & Factory Audits

Our range of supplier audits for the EV industry includes:

- Supplier Verification

- Supplier Quality Audits

- ISO 9001 Quality System Audits

- IATF 16949 Quality Management System Audits

- VDA 6.3 Process Audits

- VDA 6.3 Potential Analysis Audits

- ISO 14001 Environmental Management System Audits

- ISO 45001 Health and Safety Management Audits

- Social Compliance Audits

- Combined Audits

Manufacturing Audits and Advisory

Take advantage of our end-to-end comprehensive approach to improve your supply chain performance.

- Manufacturing Process Audits

- Process Improvement

- Production Capacity Analysis (Run & Rate)

- Quality Investigation (root cause investigation of defective products)

- Root Cause Analysis

- Corrective Action Follow up

- Process Failure Mode Effects Analysis (PFMEA)

- APQP or PPAP Review and Approval

- Continuous Improvement

Supplier Management

Pro QC’s Supplier Management Solutions enhance compliance and performance of the entire supplier portfolio by:

- Performing an on-site risk assessment

- Establishing a corrective action plan

- Verifying corrective action implementation through detailed follow-up activities

- Scheduling subsequent annual visits based on supplier risk level

- Providing a supplier portfolio dashboard and performance analysis

Our supplier management team will create a customized checklist that meets exacting requirements. The supplier management service is particularly suitable for small QA teams with a large supplier base across the globe. Pro QC assists these teams to investigate and resolve compliance and quality issues in a timely and cost-effective manner.

Pro QC International

Our Service Reports

Detailed & Actionable

- Following International & Industry Standards

24 Hours

- Report Delivery forInspections

48-72 Hours

- Report Delivery for Audits

Why Pro QC International?

Advanced Quality Analysis

Industry-leading quality dashboard, analytics, and supplier performance analysis tools and framework

Expert-Led Solutions

Pro QC has overseen successful supplier transformation projects which have helped companies buying or manufacturing EV parts or finished vehicles to achieve their quality goals

Qualified Resources

Resource transparency and the right qualifications safeguard your interests on every project at every supplier

Globally Aligned Operations

Pro QC has agile teams of mechanical and automotive engineers in 100 countries ready to meet your quality assurance needs whether it’s an auto part quality control inspection or a comprehensive IATF 16949 audit

Stringent Technical Oversight

Meticulous technical preparation, guidance throughout the engagement, and report review by senior engineers

Single Contact Point

A single contact point for quality services globally simplifies your supply chain

Stability and Expertise

Founded in 1984, over 40 years of experience make Pro QC a trustworthy and dependable quality partner

Pro QC Blog Posts & Related Offerings

Find out more about our related services by clicking below:

Click Below to Improve Product Quality with Pro QC

Contact usGet a Quote or Book a Service

We will be happy to give you more information about our quality solutions. Please fill in this form to contact us. We will respond as soon as possible.

If you would like to submit your CV, please click here.

Contact Us by Email

Contact Us by Phone

North America

+1 206 397 1145

Mexico

+52 55 9990 7885

Colombia

+57 601 9190355

United Kingdom

+44 330 094 5589

France

+33 9 7303 6784

Germany

+49 15630 810151

Australia

+61 2 8252 7691

India & South Asia

+91 227 189 7407

Asia & Asia Pacific

+886 2 2832 2990

Stability

Pro QC has been providing quality assurance, engineering and consulting services since 1984.

Global Presence

We offer a dedicated Account Manager and quality solutions in over 100 countries.

Timely Feedback

We offer online reporting and detailed reports within 24 hours of job completion.

Quality Experts

Our global engineering team has the requisite industry expertise to verify quality and conformance.